LeFiell employs all methods of inspection technologies used in the aerospace industry to assure our customers of meeting and exceeding the highest quality standards applicable across the broad range of semi-finished to finished products from simple Rod Assemblies to complex Engine Shaft Machined Forgings, Formed Engine Nozzle Coolant Tubes and Heat Exchanger Tubes used for manned space launches; large Monolithic Primary Structure like Nacelle Braces, to Complex Tubular Assemblies used in the most modern military and commercial aircraft.

LeFiell employs all methods of inspection technologies used in the aerospace industry to assure our customers of meeting and exceeding the highest quality standards applicable across the broad range of semi-finished to finished products from simple Rod Assemblies to complex Engine Shaft Machined Forgings, Formed Engine Nozzle Coolant Tubes and Heat Exchanger Tubes used for manned space launches; large Monolithic Primary Structure like Nacelle Braces, to Complex Tubular Assemblies used in the most modern military and commercial aircraft.

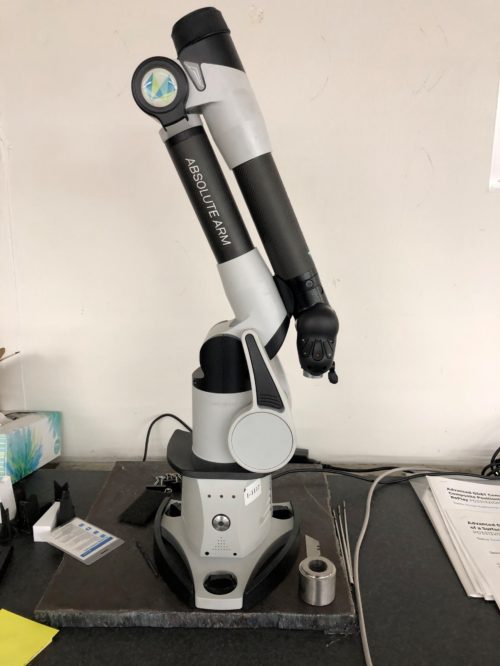

LeFiell uses a large variety of conventional inspection equipment, climate-controlled rooms for close tolerance work, and measurements including computer-controlled Romer Arms translating digital drawing data to digital inspection criteria as required by the nature of the products being produced and customer requirements.

LeFiell inspection technologies are consistent with the requirements of the global aerospace industry as it has been evolving from the mid-20th century to the mid-21st century. LeFiell has the inspection technologies in place to support both design and build-to-print products still flying from the 1950s through the most state-of-the-art new aircraft, engine, and spacecraft designs of the 21st century.